Week 4 Wrap Up

As the build season progresses, each subteam continues to work tirelessly. We aim towards a competition ready robot and are making strides in achieving our season goals.

The team will be hosting two events during the week of February 16th at the Mukwonago High School. Our Annual Open House will be on Monday, February 17th from 6pm-8pm. There, multiple levels of FIRST groups and several of our sponsors are invited to exhibit their teams and companies. The following Saturday, February 22nd, we are hosting a SWENext (Society of Women Engineers) event from 10am-12pm. Kids from grades 4th-8th will be able to participate in fun STEM activities and learn about FIRST. Stay tuned for future details.

The drivetrain is undergoing thorough testing on our practice robot.

Electrical

The electrical team has been working in conjunction with the CAD and fabrication teams to prototype and assemble new mechanisms. To test battery health, electrical used a brand new tool called a CBA (Computerized Battery Analyzer). This will allow for more efficient battery usage. Thank you to our sponsors for making this possible! The team reached out to Cross The Road Electronics and discussed ways to improve electrical components on the robot and reduce potential error.

Business

The business agenda this week concentrated on finalizing awards, design and events. As our SWENext event was confirmed, our team has created a SWENext group, SWE BEARs. Business worked to finish with edits to the Chairman’s and Woodie Flowers Awards. They will be ready to be submitted next week! The team has been busy finalizing sponsors as both the team and drive t-shirts are completed. The business team has also been working on a special project that we are ready to announce soon!

The 3D printed field has been assembled.

Strategy

A 3D printed model has been created to give the team an interactive view of the competition field. We can use this model to test out several of their strategies. Several tools are being refined and prepared for competition. The Auto Strategy Creator Tool uses data from Roblu, a scouting app, to automate match strategies easily. The Ball Flow Match Simulator helps show the possibilities of Power Cell location on the game field during a match. This week, strategy worked to finalize their scouter accountability standards and plan scouter presentations. During competition, these scouters search for the best team prospects for alliances. Strategy will continue to improve upon these tools as we approach competition season to be as efficient as possible.

The Limelight system has been attached to a turret prototype and is tracking the power port objective!

Programming

Improvements on our code continues on a daily basis. Now that key parts of the robot are taking physical form, the team is able to see their code come to life. They’ve worked to improve the autonomous and drivetrain code and were able to create subroutines that control the Color Wheel mechanism. Trello has been implemented for task management and Github has been configured as a code repository. Finally the Limelight system is properly tracking the power port autonomously. This is a huge milestone!

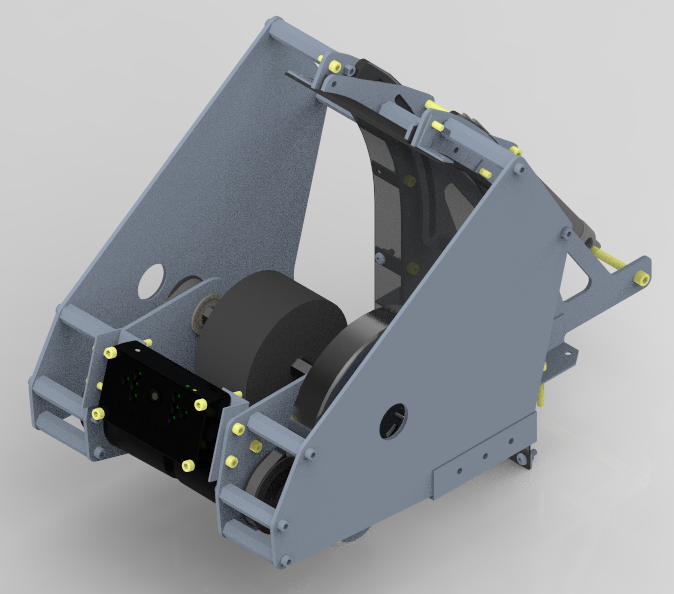

A CAD rendering of the Shooter Mechanism.

CAD

CAD hustled this week to create models of the final robot and mechanisms. Versions 1-6 of the shooter and turret were completed. The turret acts as a swivel base for the shooter; version 7 of this part is being made. The shooter launches the power cells (foam balls) into designated scoring targets. These power cells are obtained through an intake which are transferred to the hopper, a storage area for the cells. The power cells are then brought into the shooter through the tower to be scored. Designs for the tower and other prototypes continue to be made.

Fabrication

Fabrication continues to build robot components as the game elements are now completed. From CAD drawings, the metal shop has begun to build the outer perimeter of the drivetrain and the gearboxes. The team has also been working in collaboration with other subteams to make some internal improvements. For electrical, fabrication has created a reel holder for the newly acquired loads of wire.